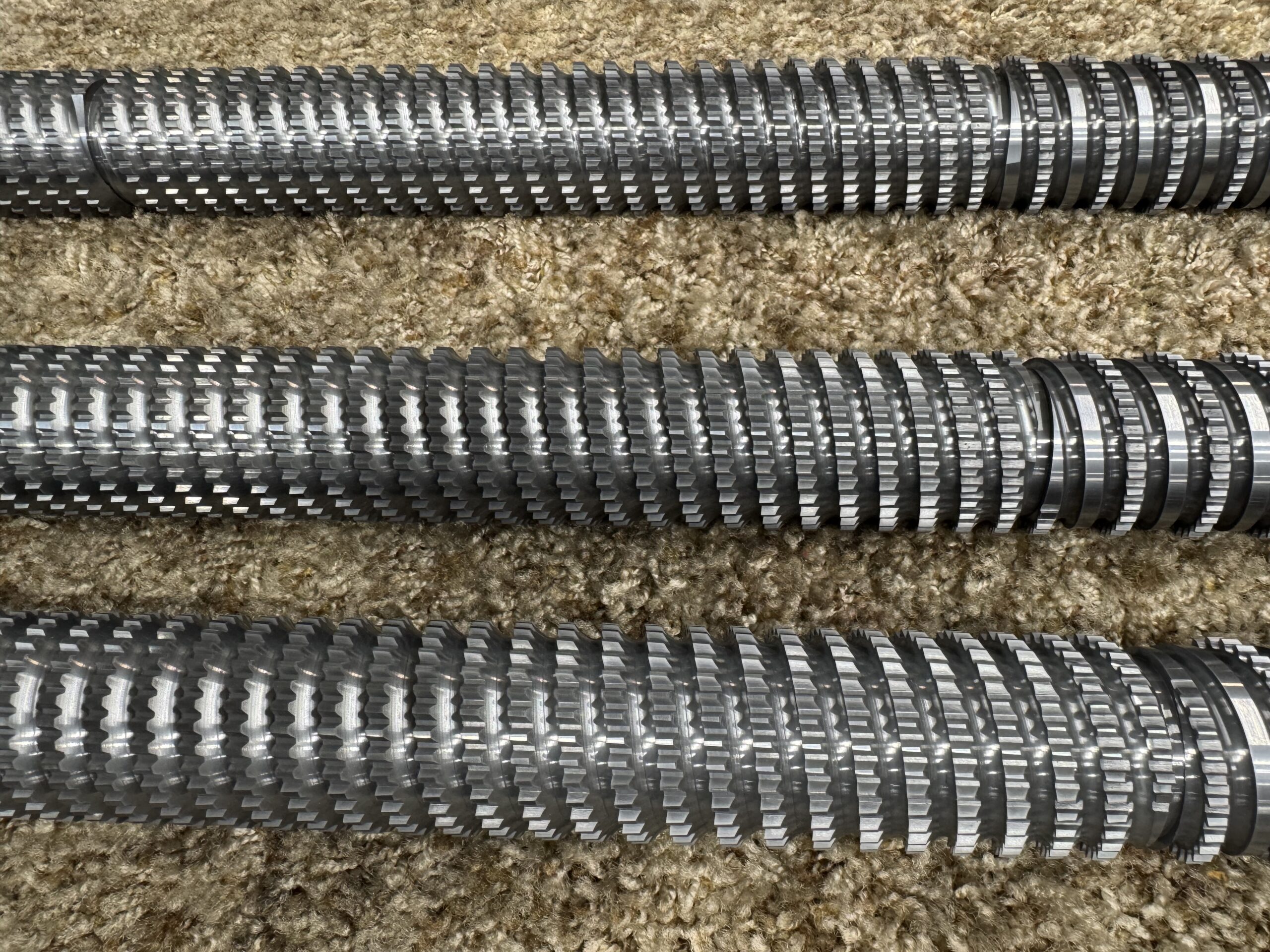

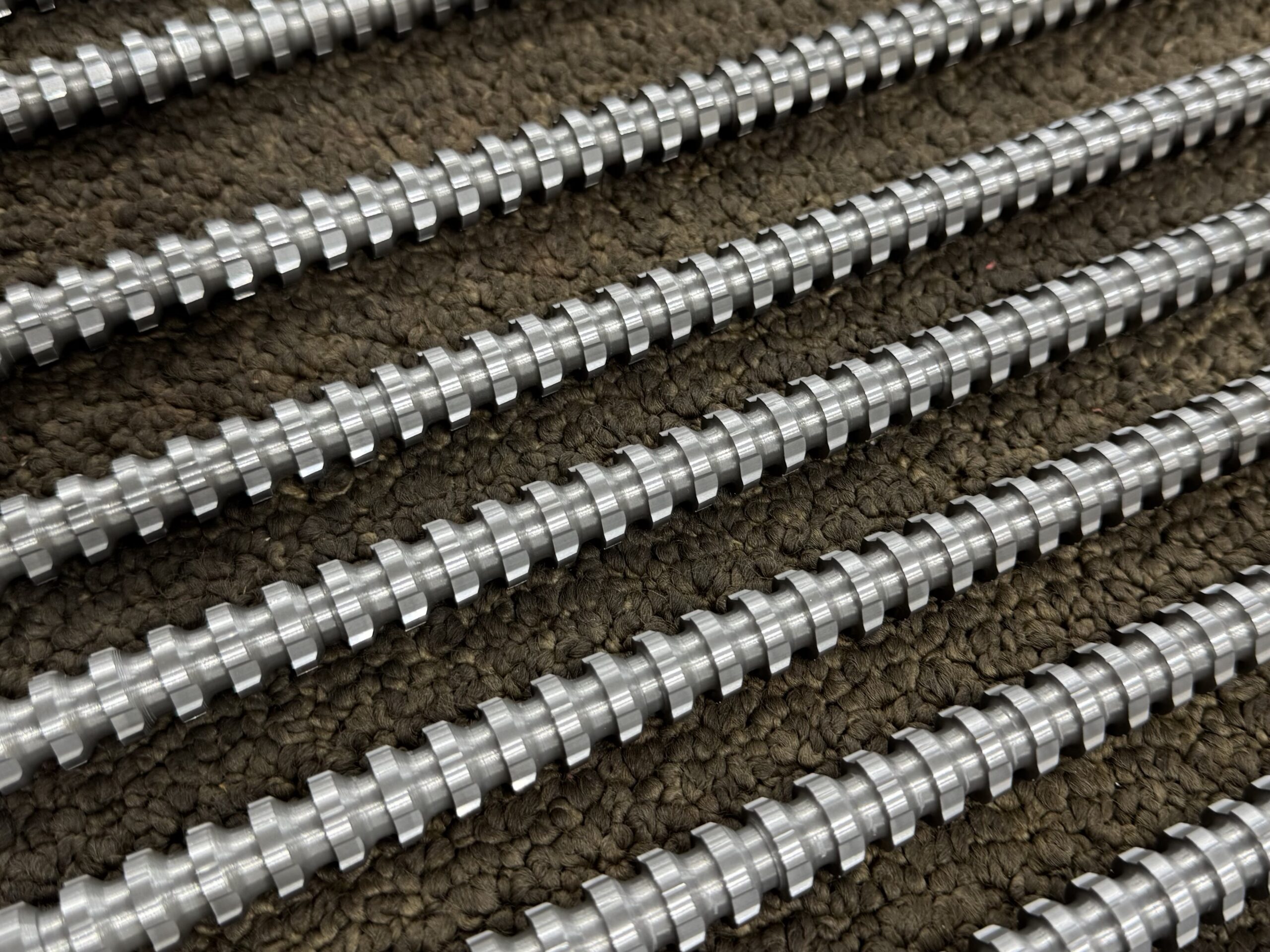

Precision Tools for Every Application

Explore Our Comprehensive Range of Broaches and Tools

Innovative Features of Our Products

Our broaches and tools are engineered to deliver unmatched performance and reliability, tailored to meet diverse industrial requirements.

High-Quality Materials

Crafted from premium-grade materials, ensuring durability and long-lasting performance in demanding environments.

Customizable Designs

Offering tailored solutions to fit specific applications, enhancing operational efficiency and productivity.

Precision Engineering

Manufactured with meticulous attention to detail, guaranteeing accurate and consistent results every time.

Advanced Technology

Incorporating the latest technological advancements to provide superior cutting and shaping capabilities.

If it can be broached, Kingsford Broach & Tool can design and build a broach to do the job.

We offer a complete line of broach pullers and turnkey broaching sysytems. We design and manufacture precision broaches and broach related products for many industies worldwide.

Round Broaches

◊ Sizing

◊ Hex

◊ Square

◊ Rectangle

◊ “D” & Double “D”

Spline Broaches

◊ Involute

◊ Straight

◊ Angular

◊ Inverted Key

◊ Spiral

Flat Broaches

◊ Inserts

◊ Rack

Form Broaches

◊ Fir Tree

◊ Serration

◊ Dovetails

Keyway Broaches

◊ Standard & Metric Standard

◊ Customer Specifications

Arms

◊ Magwell

◊ Rifling

◊ Breech

◊ We also specilize in Cam Broaches, Pot Broaches, Punches, Dies, and CNC Driven Keyways.

Broach Pull Heads and Pullers

RD Type Automatic Pull Head

The RD pull head is recommended for pull down broaching operations where chips fall or are washed downward by coolant onto the pull head. The special design of the head provides an umbrella top to shed falling chips and a hole the length of the puller for chips to wash through. This head is identical in operation to the R Type and can also be provided with a radial index key. This puller fits all standard broaching machines. View the RD Type Automatic Pull Head Size Chart and Cross Section Drawing.

R Type Automatic Pull Head

This four jaw broach pull head assures positive and automatic broach connection on horizontal or pull-up broaching machines. When the broach connects, a coil spring moves a sleeve forward engaging and locking all four jaws around the broach shank. The broach is disengaged by contact of the sleeve against preset stops, which moves the sleeve back, unlocking the jaws. The puller can be provided with a radial index key. This puller fits all standard broaching machines. View the R Type Automatic Pull Head Size Chart and Cross Section Drawing.

Round Pin Type Broach Pull Head

Pin type pull heads are used to handle broaches less than 1/2″ in diameter. The broach shank is securely held in position by spring pressure on the cross pin. Removal is effected manually by a slight pressure on the cross pin. Automatic release is provided by a plunger above the broach bore, causing the cross pin to recede on contact with a preset stop. For radial broach positioning, index cross keys are inserted into the pull head to provide proper alignment. View the Round Pin Type Broach Pull Head Size Chart and Cross Section Drawing.

Horizontal Keyway Puller

Designed primarily for keyway broaches or types of broaches using rectangular shanks, this pull head can be manually or automatically operated. Proper pulling alignment is assured as the head holds the broach in position against flat surfaces and provides a positive broach locking action. The keyway broach pull head is built in two sizes, the number (0) for broach shanks up to a maximum 3/4″ x 3/4″ and the number (1) head for shanks with a maximum of 1 1/2″ x 1 1/2″. View the Horizontal Keyway Puller Size Chart and Cross Section Drawing.

Keyways

By clicking on this button below you will access the Series 500 & 600 Standard Keyway Broach Chart.

ALL KEYWAYS THOUGH 1/2 ON THE CHART ARE NOW PM-M4.

Order broaches by numbers found in first column. If this chart does not include a cutter that meets your specifications, simply order keyway broach, stating size of keyway and hole, material to be broached and length of part. Standard and special blanks are normally stocked in all sizes.

Turnkey Systems

As a service to our customers, Kingsford Broach & Tool, Inc. offers manufacturers complete turnkey broaching solutions. Our engineers design automated or manual broaching cells to operate with, or independent of, manufacturing production lines.

Our complete turnkey systems are designed to be incorporated into your new broaching machines or your existing broaching machine. We can also incorporate turnkey systems to refurbish and modify a used machine to suit. We design and build all fixtures, holders, and broaches to maximize your manufacturing process to meet your production goals.

We also offer our customers the option of stocking commitments and broach maintenance plans.

Contact us for more information on complete turnkey systems.

Our complete turnkey systems are used by manufacturers worldwide, in firearms, automotive, hand tool, gear companies, and job shop applications.

K Coat

How would you like to increase your broach life by 25 to 40% over TiN coated tools?

For more than a decade, Kingsford Broach & Tool, Inc. has partnered with Richter Precision, Inc. in developing the industry’s first broaching specific tool coating – “K” Coat.

“K” Coat was specifically engineered to provide maximum performance and longer tool life in all broaching applications.

Why “K” Coat?

- Effectively protects cutting edges from wear

- Simultaneously assures reliable chip evacuation

- Extend resharpening capacity over normal sharpening

- Surface hardness is close to ceramic carbide cutting tools (84/85 hv/hrc)

- Coefficient of friction: 0.35

- Maximum working temperature: 450ºc/840ºf

- Color: Bronze/Grey

- Up to 60% tool life increase over uncoated tools

- Up to 30% tool life increase over TiN coated tools

- Up to 15% increase in tool life over TicN coated tools

- Cost effective!

Contact us today and see how Kingsford’s “K” Coat can dramatically impact your tooling costs!